Why do some food factories get perfect, clean bakes every time – while others fight sticking, smoking trays and rejected batches?

If you run an industrial bakery, QSR chain, or food-processing plant, you already know: choosing the right baking paper jumbo roll supplier can quietly decide your yield, hygiene score, and even your brand reputation. But how do you pick the right partner and spec when everyone claims to offer “food-grade, non stick, high temperature” rolls?

In this guide, we’ll walk through what smart buyers look for when sourcing a baking paper jumbo roll for food factory lines, how silicone coated non stick baking paper jumbo rolls are really made, and why brands that prepare for shows like Modern Bakery Moscow are upgrading their supply chain to runjiapaper.

1. What Exactly Is a Baking Paper Jumbo Roll for Food Factories?

A baking paper jumbo roll for food factory is not just “big retail baking paper.” It is engineered for:

Continuous operation on industrial sheeters, slitters or die-cut lines

Stable release and non stick performance across thousands of cycles

High-temperature resistance (usually up to 220–230°C)

Consistent GSM and thickness to avoid web breaks and waste

When you select a baking paper jumbo roll supplier, you’re not just buying paper – you’re buying process stability. At runjiapaper, each jumbo roll is designed for converting, baking, steaming, roasting or food-packaging scenarios, not just home ovens.

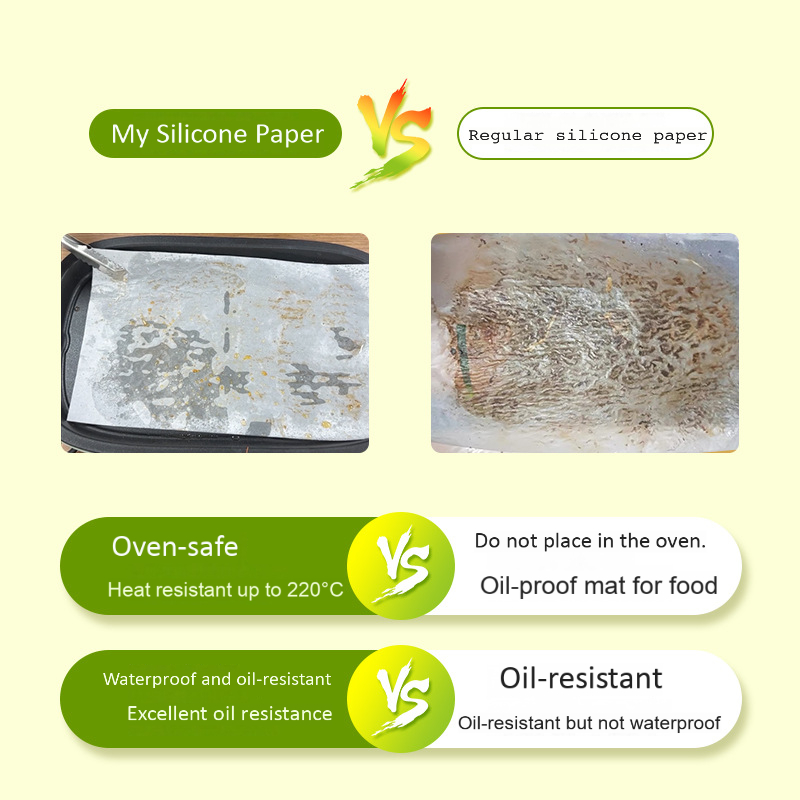

2. Why Silicone Coated Non Stick Baking Paper Jumbo Rolls Make a Difference

The heart of performance lies in the coating.

High-quality silicone coated non stick baking paper jumbo rolls use:

Food-grade silicone on one or both sides

Even coating weight for consistent release

Base paper from 100% virgin pulp or tailored blends

This means you get:

Less sticking and tearing

Cleaner product surfaces

Less oil/fat needed on trays

Faster tray cleaning and turnaround

If your current supplier never talks about coating weight, curing curve, or release performance at different fats and sugars, it’s time to compare them with a specialised baking paper jumbo roll supplier like runjiapaper.

3. Key Specs to Check Before You Choose a Baking Paper Jumbo Roll Supplier

To help you compare options, here’s a spec overview table you can use when talking with any baking paper jumbo roll supplier.

| Item | Typical Range / Option | Why It Matters for Food Factories |

|---|---|---|

| Base Paper GSM | 35–45 gsm | Impacts strength, non stick performance and cost per sheet |

| Roll Width | 280–1650 mm (custom) | Must match your sheeter / oven tray width |

| Roll Diameter | Up to 1000–1200 mm (custom) | Determines changeover frequency and storage planning |

| Core Size | 3″ / 6″ (custom) | Must match your unwinding shafts and automation |

| Coating Type | Food-grade silicone (1-side or 2-side) | Ensures stable non stick and safe contact with food |

| Temperature Resistance | 220–230°C (short-term higher) | Critical for bakery lines and continuous ovens |

| Application | baking paper jumbo roll for food factory, roasting, steaming | Ensures spec matches your exact process |

| OEM/Private Label | Custom branding & documents | Needed for industrial brands and private label programs |

A professional baking paper jumbo roll supplier like runjiapaper will walk through each line with you, instead of just emailing a one-line “40gsm, 1000mm, FOB” quote.

4. How runjiapaper Supports Food Factories as a Baking Paper Jumbo Roll Supplier

As an export-focused baking paper jumbo roll supplier, runjiapaper focuses on B2B buyers:

For food factories & industrial bakeries

Custom width/diameter for each baking paper jumbo roll for food factory line

Stable silicone coated non stick baking paper jumbo rolls designed for continuous production

Technical support on un-winding, slitting and cutting performance

Batch traceability and quality certificates for audits

For converters and packaging manufacturers

Jumbo rolls optimised for slitting and sheeting at high speed

Consistent GSM and moisture content to reduce breaks and web tension problems

Flexible MOQ for new product development or line testing

If you are preparing your sourcing list ahead of Modern Bakery Moscow, updating your baking paper jumbo roll supplier to runjiapaper can be a powerful differentiator when buyers ask about traceability, stability, and non stick performance.

5. Typical Applications of Silicone Coated Non Stick Baking Paper Jumbo Rolls

Well-specified silicone coated non stick baking paper jumbo rolls support a wide range of applications in the food industry:

Industrial baking: bread, cookies, cakes, pastries, pizza bases

Frozen foods: par-baked products, pre-fried snacks, ready meals

Confectionery: chocolate decorations, nougat, candies

QSR & central kitchen: tray-lining for chicken, fries, baked rice, etc.

Food packaging: wrapping greasy or high-fat items that need clean presentation

When talking to your baking paper jumbo roll supplier, always describe your specific oven type, temperature, baking time and product type – runjiapaper can then adjust the spec of each baking paper jumbo roll for food factory use-case.

6. How to Evaluate a Baking Paper Jumbo Roll for Food Factory Use

Here’s a simple checklist to test samples from any baking paper jumbo roll supplier:

Non stick performance

Does product release cleanly without tearing or leaving residue?

Colour & odour

Is the paper clean, uniform and neutral, with no strange smell?

Silicone transfer

No visible silicone residue on food; complies with migration standards.

High-temperature stability

Paper should not darken, smoke or curl excessively at your process temperature.

Mechanical strength

Does the paper resist tearing when loaded, transferred and de-panned?

Consistency between rolls

Each batch of silicone coated non stick baking paper jumbo rolls should behave the same.

runjiapaper provides detailed test reports and production data so your quality team can lock in specs with confidence.

7. FAQ – Common Questions About Baking Paper Jumbo Roll Supply

Q1: What GSM should I choose for baking paper jumbo roll for food factory use?

For cookies and light pastries, 38–40 gsm is common; for heavier products or more demanding conditions, some food factories prefer 40–42 gsm. As your baking paper jumbo roll supplier, runjiapaper will recommend GSM based on your oven type, product and line speed.

Q2: Why do I need silicone coated non stick baking paper jumbo rolls instead of uncoated paper?

Uncoated or simple greaseproof paper may not provide reliable release, especially with high fat or sugar content. Silicone coated non stick baking paper jumbo rolls offer a stable release surface, reducing sticking, waste, and cleaning time, which is critical for industrial bakeries.

Q3: Can you customise width and roll diameter for our existing converting machines?

Yes. As a specialised baking paper jumbo roll supplier, runjiapaper can customise width (e.g. 280–1650 mm) and diameter (e.g. up to 1000–1200 mm) to match your sheeter, cutter and packaging lines, so you don’t need to change your equipment.

Q4: How do you ensure quality and traceability for large orders?

Each batch of baking paper jumbo roll for food factory orders from runjiapaper is produced under documented procedures with batch numbers, raw material records and coating parameters. We provide COA, MSDS and relevant food-contact documentation as needed for audits or events like Modern Bakery Moscow.

Q5: Can I mix different specs in one container?

Yes. Many buyers load several specs of silicone coated non stick baking paper jumbo rolls in one 40HQ to optimise freight. Our team designs loading plans to keep rolls safe and make your logistics more cost-effective.

8. Ready to Talk to a Baking Paper Jumbo Roll Supplier That Understands Food Factories?

If you’ve read this far, you’re not just price shopping – you’re searching for a baking paper jumbo roll supplier who understands real baking paper jumbo roll for food factory production, non stick performance, and documentation.

At runjiapaper, we focus on B2B customers who need:

Stable, food-grade silicone coated non stick baking paper jumbo rolls

Custom specs for bakery, QSR and food-processing plants

Export-ready documentation and 40HQ loading plans

Fast, professional responses (usually within 24 hours)

Share Your Specs – Get a Custom Solution

Fill in the form on your website with:

Product: baking paper jumbo roll for food factory / silicone coated non stick baking paper jumbo rolls

Required width, diameter, GSM and core size

Application (cookies, pastries, pizza, chicken, confectionery, etc.)

Destination port and expected volume per month