Are you sure your baking paper manufacturer is the one actually coating your rolls—and not just a trader? If you’re scaling private-label or food-service supply, that single question can decide your margins, lead time, and product claims.

This guide compares what matters in a parchment paper manufacturer or silicone coated baking paper factory, shows how runjiapaper audits quality, and helps you spec faster with ready-to-copy checklists and a pricing/spec table. (Yes—we’ll also be at the China Import and Export Fair for live sampling and fast quotations.)

Why manufacturers (not traders) protect your margin

Coating control = performance: True factories control silicone coat-weight (g/m² per side) and curing, which drives non-stick, oil resistance, and release behavior in your ovens and lines.

Traceability you can print on pack: Pulp origin, FDA/BRC/ISO docs, migration tests—auditable from base paper to finished rolls/sheets.

Stable lead time: Your MOQ blocks real machine time vs. ad-hoc resales.

Private-label speed: In-house slitting/re-winding, die-cutting, boxing, and palletization reduce changeover loss and errors.

At runjiapaper, we operate silicone double-sided coating + slitting + rewinding + auto-boxing, built for jumbo rolls, industrial sheets, and retail small rolls.

What to ask every baking paper manufacturer

Paper Base: 100% virgin wood pulp? Gsm range (e.g., 35–60 gsm)?

Coating: One-side or double-side silicone? Target coat-weight per side?

Temperature: Verified bake rating (≤230 °C/450 °F) and freezer rating (to −30 °C)?

Formats: Jumbo width (e.g., 380–1800 mm), small roll (e.g., 30/45/50 m), sheets (pre-cut sizes).

Compliance: FDA, BRC/Global Standard for Packaging, ISO 9001, FSC/CoC, Kosher/SEDEX.

Packaging: OEM color box, blade type, export cartons, barcode sets.

QC Proof: Release force, oil-kit, fiber-tear, migration/overall MOH tests—send latest reports.

Logistics: Pallet plan, carton stacking map, HS code, port options, lead time windows.

Quick spec & pricing baseline

| Item | Typical Spec | Lead Time | MOQ | Notes |

|---|---|---|---|---|

| Jumbo Rolls | 39–41 gsm, 1000–1500 mm width | 20–30 days | 5–10 tons | For industrial rewinders |

| Retail Small Rolls | 38–41 gsm, 30/45/50 m, double-side silicone | 20–30 days | 10,000+ | OEM box + blade |

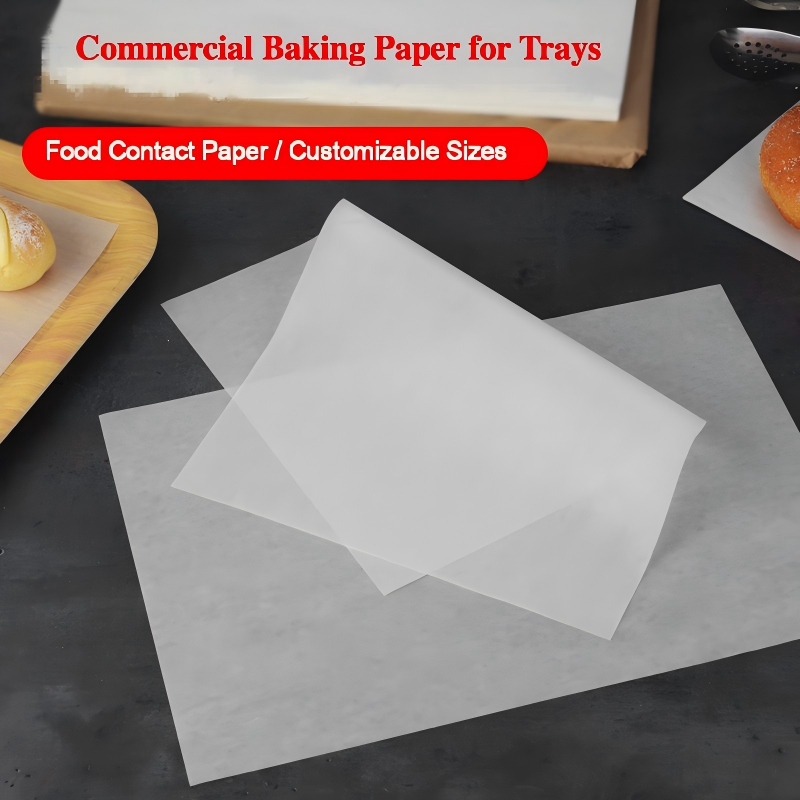

| Pre-cut Sheets (Bakery/Food-service) | 40 gsm, 400×600 mm / US half & full sheet | 15–25 days | 100,000+ | Flat/accordion pack |

Meet us at the China Import and Export Fair for live pull/tear demos and release tests; ask for the runjiapaper QC checklist.

Why runjiapaper wins repeat orders

Consistent release (sheet after sheet) thanks to controlled silicone coat-weight and curing.

Audit-ready docs (FDA/BRC/ISO) and migrating to FSC/CoC lines on request.

OEM/ODM speed: artwork, boxing, and pallet plans approved in days—not weeks.

Scale: Monthly capacity for jumbo + retail lines with 100% strict QC gates.

FAQs

Q1. Can a baking paper manufacturer match our oven and line requirements?

Yes—runjiapaper aligns gsm, coat-weight, and sheet/roll formats to your ovens, guillotines, and rewinders.

Q2. Do you supply as a parchment paper manufacturer for both jumbo and retail?

Yes. Jumbo rolls for converters + retail small rolls and pre-cut sheets for brand owners/food-service.

Q3. Are you a silicone coated baking paper factory or a trader?

We are a silicone coated baking paper factory with in-house coating, slitting, rewinding, and auto-boxing.

Q4. Can you handle multi-SKU private label?

Yes—color boxes, blades, labeling, and carton patterns per channel (retail/club/food-service).

Ready to spec? Get a custom quotation in 24 h

Tell us: gsm, size (roll/sheet), packaging, monthly volume, destination port.

We’ll send: spec sheet + pallet plan + CIF/FOB quote + certificates.

CTA → Fill the form below to get samples & pricing (responds within 24 h).