Have you ever wondered why two “non-stick” rolls can look identical, yet one releases pastries perfectly while the other tears, curls, or leaves stubborn residue on the tray? If you’re buying baking paper rolls wholesale, the difference isn’t the label—it’s the coating consistency, base paper strength, and winding control that a professional baking paper supplier manages every day.

This article is written for B2B importers, distributors, foodservice wholesalers, and private label brands who need non stick baking paper rolls wholesale with stable performance. (If you’re preparing for SIGEP Asia, keep this checklist ready for supplier comparisons.)

Brand note: This guide is published by runjiapaper.

What “Non-Stick Baking Paper Rolls Wholesale” Actually Means

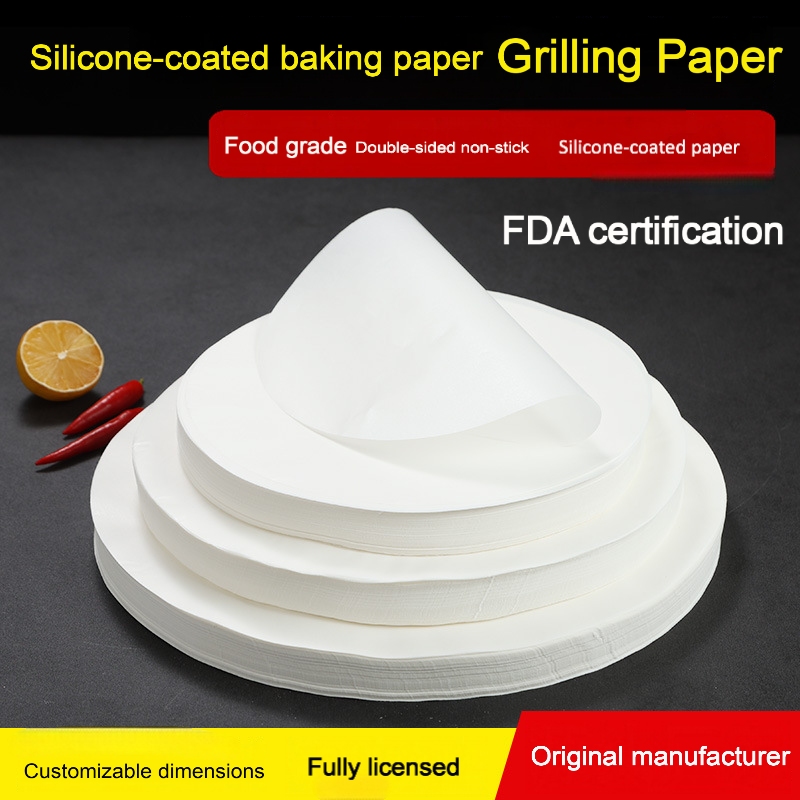

Non stick baking paper rolls wholesale usually refers to food-grade baking paper in roll form designed for clean release, heat resistance, and grease resistance—typically achieved through silicone coating or equivalent non-stick treatment (depending on the grade and market requirement).

Wholesale roll formats are commonly used for:

Retail private label rolls (supermarkets / e-commerce)

Foodservice & catering rolls (restaurants / central kitchens)

Bakery production (high-frequency baking)

A capable baking paper supplier should help you match the right roll specification to your end-use—so you don’t pay for features you don’t need, and you don’t under-spec and get complaints.

Why Buyers Get Complaints (And How a Baking Paper Supplier Prevents Them)

Most complaints about baking paper rolls wholesale come from three root causes:

Release inconsistency → patchy coating or wrong coating side

Tearing / poor cutting → GSM too low for roll length, poor slitting

Dispensing issues → unstable winding tension, wrong core size

If you want repeat orders, treat non stick baking paper rolls wholesale like a technical product—not a commodity.

The Spec Table You Should Send Before Asking for a Price

To get accurate pricing and faster sampling, send this spec sheet to your baking paper supplier. It also reduces back-and-forth and prevents “same name, different product” mistakes.

Wholesale Baking Paper Rolls Specification Table (Copy & Use)

| Spec Item | Common Options | What It Impacts | Buyer Recommendation |

|---|---|---|---|

| Base Paper GSM | 30–45gsm common (custom available) | Strength, tearing, stiffness | Longer rolls need stronger GSM |

| Non-Stick Type | Silicone coated / treated non-stick | Release performance | Ask for single vs double side |

| Coating Sides | 1 side / 2 sides | Consistency of release | Double side often reduces complaints |

| Roll Width | 30 / 38 / 40 cm or custom | Shelf fit / tray fit | Match local market standard |

| Roll Length | 5–20m retail / 50–100m+ foodservice | Value perception + handling | Choose by channel and dispenser |

| Core ID | 25 / 38 mm or custom | Dispenser compatibility | Confirm with dispenser supplier |

| Heat Resistance | Suitable for baking temperatures (by standard) | Safety + performance | Request test method used |

| Grease Resistance | High | Oil soak-through control | Important for meat & pastries |

| Paper Color | White / Brown | Market preference | Brown often for “eco” positioning |

| Packaging | Shrink / color box / carton / OEM | Export safety + shelf look | Confirm carton strength for export |

| Documents | Food contact declarations, batch info | Retail onboarding + customs | Ask what’s available for your market |

At SIGEP Asia, many products look similar on the booth table. This spec table helps you compare offers like a pro.

Best-Selling Wholesale Configurations (By Channel)

A practical baking paper supplier should recommend one “safe best-seller” to start, then optimize later.

1) Retail Private Label Rolls

Consumer-friendly roll length (common retail range)

Clean cutting, smooth winding

OEM color box + barcode + carton marks

This is the most common format for baking paper rolls wholesale in supermarkets.

2) Foodservice / Catering Rolls

Longer rolls for operational efficiency

Stronger base paper to avoid tearing

Export-ready cartons for bulk shipping

Great for restaurants and central kitchens buying non stick baking paper rolls wholesale.

3) Bakery Production Rolls

Focus on coating uniformity + grease resistance

Stable release to prevent tray sticking

For bakeries, performance consistency matters more than saving a few cents.

How to Evaluate a Baking Paper Supplier

Before you place your first order for baking paper rolls wholesale, ask your baking paper supplier:

Can you provide single-side vs double-side options for non-stick?

How do you control coating uniformity (to prevent patchy release)?

What’s your slitting quality control (clean edges, low dust)?

How do you control winding tension (no telescoping, stable rolls)?

What export packaging do you recommend for my route and climate?

Can you support OEM/private label packaging and carton marking?

What are your MOQ, lead time, and sample plan?

runjiapaper uses this same logic when recommending specs—because fewer complaints = more repeat orders.

Why runjiapaper Is a Strong Choice for Wholesale Baking Paper Rolls

As a baking paper supplier, runjiapaper focuses on stable export supply for baking paper rolls wholesale and non stick baking paper rolls wholesale, with clear specifications, OEM packaging support, and practical guidance on roll performance (release, tearing, dispensing, and packaging).

If you’re meeting suppliers at SIGEP Asia, bring your target spec—then compare samples side-by-side using the table above.

FAQ:

Q1: Single-side or double-side non stick baking paper rolls wholesale—what should I choose?

For most baking use, double-side non-stick typically delivers more consistent handling and release. Single-side may be chosen for cost-sensitive markets or specific applications.

Q2: What should I send to a baking paper supplier to get an accurate quote?

Send: GSM, coating type, coating side(s), width, length, core ID, paper color, packaging style (shrink/box/OEM), quantity, destination port, and required documents.

Q3: Why do some baking paper rolls wholesale tear easily?

Most common reasons: GSM too low for the roll length, weak base paper, poor slitting, or unstable winding tension. Specify your usage channel so the supplier matches the right grade.

Q4: Why do some rolls stick even though they are “non-stick”?

Patchy coating, wrong coating side, or mismatch between product grade and baking condition can cause sticking. Ask the supplier for coating side confirmation and performance guidance.

Q5: Can a baking paper supplier provide OEM/private label packaging?

Yes. Many can provide color boxes, shrink wrap, barcode placement, carton marking, and shipping marks. Confirm artwork format and MOQ for OEM runs.

Get a Fast Quote (Fill the Form)

If you’re sourcing baking paper rolls wholesale or non stick baking paper rolls wholesale, send your target specs (GSM, width, length, core, packaging) and destination. runjiapaper will reply with:

A best-selling spec recommendation for your channel

Quotation with packaging options

Sample plan + lead time guidance

Please fill in the inquiry form at the bottom of this page to get a fast quotation from runjiapaper.