Have you ever wondered why a roll that looks “premium” on arrival suddenly sticks, curls, or smokes when it hits real ovens and real production speed?

If you’re searching for a silicone coated baking paper supplier, comparing baking paper rolls wholesale, or qualifying a reliable parchment rolls supplier, you’re not just buying paper—you’re buying repeatable release performance, roll stability, and export-ready packing. And when sourcing activity spikes around industry hot spots like IBAKTECH, buyers who move fast and specify correctly win the season.

This Western-style buyer guide is built to keep readers scrolling (low bounce) and help you place repeat orders with confidence.

Brand reference: runjiapaper.

Quick Answer (What Works Best for B2B Buyers in 2026)

For oily, sugary, and high-heat baking: silicone coated baking paper is typically the most reliable release option.

For bulk roll programs: choose a supplier that controls winding, core strength, GSM tolerance, and coating consistency.

For repeat orders: lock specs in writing (tolerances + QC checkpoints) before shipment #1.

Why “Non-Stick” Fails After the First Container

Most problems start after the sample stage. Common root causes:

Coating drift (release changes from batch to batch)

Wrong coating side (single vs double sided wasn’t clarified)

Roll defects (telescoping, wrinkles, uneven edges)

Heat mismatch (paper browns/curls sooner than expected)

Weak packaging (cartons crush, rolls deform in transit)

A professional silicone coated baking paper supplier should be able to show how they control these issues—not just promise “non-stick.”

Silicone Coated Baking Paper vs Standard “Non-Stick” Paper

Many products are marketed as “non-stick,” but the structure matters:

Silicone coated baking paper: designed for consistent release across different foods and temperatures

Treated or light-coated “non-stick”: can work for basic use, but often varies more by batch and application

If your customers bake pizza, pastries, cookies, or frozen-to-oven items, silicone coating usually reduces complaints and rework.

Baking Paper Rolls Wholesale: The Specs That Protect Your Margin

When you buy baking paper rolls wholesale, performance depends on more than paper grade. Confirm:

1) Roll Dimensions (for converting and packing lines)

Width, length, max roll diameter

Core ID (and core strength requirement)

2) Winding & Handling

Winding tension standard (prevents telescoping)

Edge quality standard (reduces tearing and waste)

Splice policy (allowed/not allowed + marking)

3) Packing & Shipping

Rolls per carton, carton strength, compression resistance

Palletizing (if used) and container loading plan

A strong supplier makes these specs easy to confirm—fast, clearly, and in writing.

Parchment Rolls Supplier: What “Reliable” Means in B2B

A reliable parchment rolls supplier doesn’t just ship rolls—they support a repeat program:

Consistent release performance

Stable tolerances and batch traceability

Export packing that protects rolls in long transit

Fast reorders for peak season

That’s exactly what many importers and distributors need when demand increases around trade events like IBAKTECH.

Comparison Table

| What You’re Buying | What to Request | Why It Matters | What Can Go Wrong |

|---|---|---|---|

| Silicone coated baking paper | coating type + side (1S/2S) + tolerances | release stability | sticking, residue |

| Baking paper rolls wholesale | roll specs + winding standard + core strength | smooth converting | telescoping, wrinkles |

| Parchment rolls supply | packing spec + QC checkpoints + traceability | repeat orders | batch drift, crushed rolls |

This format helps readers “self-qualify” quickly and keeps bounce rate low.

FAQ

Q1: How do I choose a silicone coated baking paper supplier for repeat orders?

Look for written tolerances, QC checkpoints, and proof of consistent coating and winding standards. A good silicone coated baking paper supplier can explain how they control batch-to-batch release.

Q2: What specs should I send when buying baking paper rolls wholesale?

Send width, length, max roll diameter, core ID, splice policy, and packing requirements. Clear specs reduce mistakes in baking paper rolls wholesale programs.

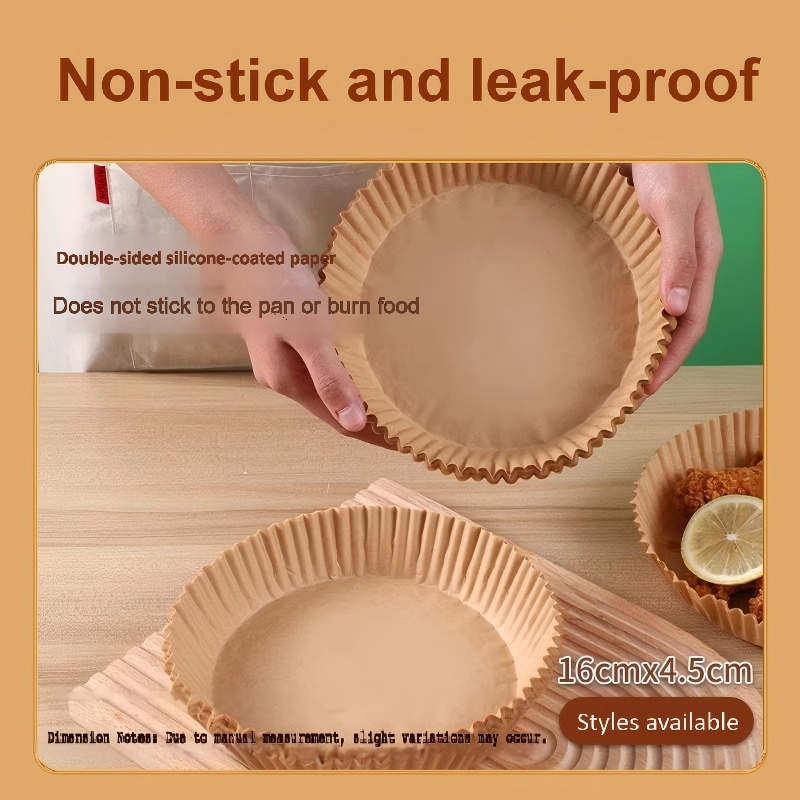

Q3: Single-sided or double-sided silicone coating—what should I choose?

Single-sided can work for controlled handling. Double-sided is safer for flipping, stacking, or high-oil products where mistakes happen.

Q4: Why do rolls telescope or wrinkle during shipping?

Usually winding tension, core quality, or carton compression. A professional supplier should define winding standards and carton strength.

Q5: Can a parchment rolls supplier support private label?

Yes. Many programs support custom cartons, barcodes, and multilingual labels—depending on volume and market needs.

Get a Fast Quote From runjiapaper (Fill the Form)

If you’re evaluating a silicone coated baking paper supplier, sourcing baking paper rolls wholesale, or looking for a stable parchment rolls supplier, fill out the form with:

Destination country/port

Application (pizza / pastry / frozen / general baking)

Coating preference (single-sided / double-sided silicone)

Roll specs (width/length/core ID/max diameter)

Packing requirement (rolls/carton, pallet or non-pallet)

Monthly volume + target lead time

Fill in the form now and runjiapaper will send a recommended spec + packing proposal designed to reduce complaints, improve roll stability, and support repeat wholesale orders.